- Send your mail at

- info@smfengg.co.in

Manufacturing

Our Manufacturing Products

2-Station BTA Deep Hole Drilling Machine For DTH Bits

A 2-STATION BTA DEEP HOLE DRILLING machine features a unique execution with special job rotation capabilities. The job is securely clamped using a power-operated self-centering chuck on one end and a power-operated self-centering steady rest on the other end. The drilling process involves rough drilling with a maximum diameter of 48, reaching a depth of 400mm in the first station. Subsequently, the job is indexed to the second station to perform finish drilling with a spherical end shape. This design allows for precise and efficient drilling operations with a two-stage process for optimal results.

Heavy Duty Special Milling Head

Heavy duty special milling head with backlash free drive spindle with arbor & its supports with

milling cutters of dia 350 to do the milling surface with end chamfers of total width 30mm for M/s

DLW,VARANASI.

To Access Pedistal And Ajumenths Antena

Our specialized milling head is designed for precise key way milling in bores with a minimum diameter of 75. This innovative add-on equipment, integrated with ballscrew and servomotors, delivers exceptional performance, contributing significantly to the success of M/s EUROFLEX TRANSMIS.

Automatic Self-Centering Leg Fixture for Welding

Key Specifications and Special Features:

- The fixture is equipped with a power-operated self-centering clamping mechanism.

- It features a central hydraulic cylinder positioned underneath the body. The piston's vertical movement operates three bell crank levers, simultaneously actuating three self-centering plungers.

- Three clamping plungers are guided in guide bushes, connecting to clamping levers on one end and self-centering plungers on the other through a connecting plate. This design enables the simultaneous in-and-out movement of clamping levers for effective component clamping and declamping.

- A hardened cover is provided at the center of the body to support and protect the clamped component.

- The component is securely clamped both at the top and bottom using suitable clamps attached to the clamping lever.

- The fixture is specifically designed to shield guided members from slag formed during welding processes.

Portable 3-Axis Deep Hole Drilling Machine for Router Turbine Blades

This portable drill head is equipped with torque monitoring and thrust monitoring features, along with 3-axis manual movement. It is specifically designed for fixing drill holes with taper reaming in rotor turbine blades. (Supplied to BHEL, Chicago).

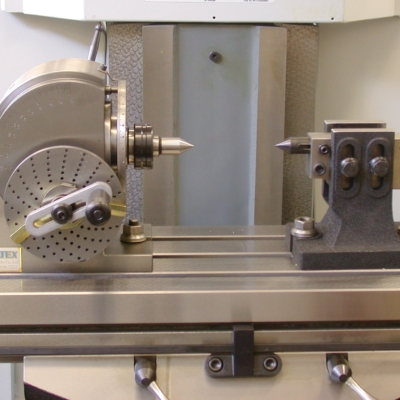

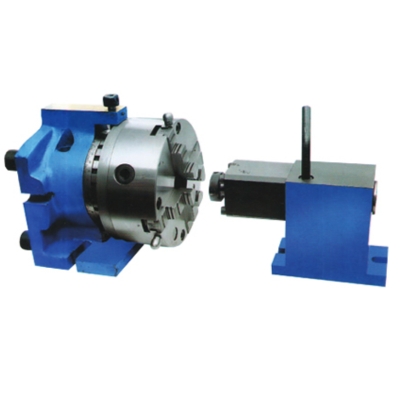

CNC Indexing Head

The CNC indexing head serves as an add-on equipment for CNC horizontal milling machines, specifically designed for external spline cutting on rocdrill bits for M/s SAIDEEPA ROCDRILLS PVT LTD. You can watch the equipment in action in the following video link.

Hydraulically Operated Leg Fixture with 3-Indexings

This leg fixture is equipped with three indexings and operates hydraulically. It is designed for milling a 120-degree profile on legs, enhancing the machining capabilities of the center.

Collet Fixtures for Mazak Machining of Cones

These collet fixtures are specifically designed for holding cones of different sizes in the bore, facilitating the drilling operation on a Mazak machining center for M/s ATLAS COPCO.

Specialized 2-Axis CNC Interpolating Buffering Equipment

We have designed and manufactured a unique piece of equipment to catch a ribbon moving at a high speed of 20m per sec. This equipment is capable of transporting the ribbon to the winder at a distance of 5 meters, utilizing 2 CNC interpolating axis movements. The equipment features a spindle with runout precision of 1 to 2 microns, precise positioning controls ranging from 1 micron to 2 microns, and the ability to vary endstop positions by 1 micron to 2 microns. It was supplied to M/s VIJAI ELECTRICALS LTD, Chicago.

Backlash free gear boxes

Backlash free gear boxes with double pinion and rack arrangement.

Hollow Spindle Gear Box for Core Drilling Rigs

Our specialized hollow spindle gear box is designed for a diameter of 117 pipes, catering to the unique requirements of core drilling rigs.

Power-Operated Self-Centering Collet Fixture for Clamping 6 ½" Digger Bit on U-Cam on Vertical Machining Center

Flush Hole Drilling Fixture to Maintain 180 Degrees on Drilling Machine

Hydraulically Operated Button Pressing Fixture for Clamping 6 ½" Digger Bit